In the "production now" laboratory, the digitization and networking of production systems is being investigated. As a result of networking, such production systems often generate a great deal of measurement data, diagnostic messages and process signals which are recorded and archived but often cannot be evaluated at present. In addition to the large volume of data, the challenge is that the data is often complex and unstructured. Strategies for the effective preparation and use of this data thus form the basis for the use of networked production systems in practice.

Goals and idea

The name of the laboratory, "production now", was chosen in reference to "Google now". "Google now" is a networked system for private users, which advertises by providing its users with "the right information at the right time", e.g. weather data, traffic information, distances to shops, etc. The basic principle of this system is to link and filter the information in a context-sensitive way. Thus, the user does not have to search for the information, but the system takes over this task. Transferred to the automation industry, the extension "now" would stand for example for the context-sensitive availability of information and its linkage to higher-value information.

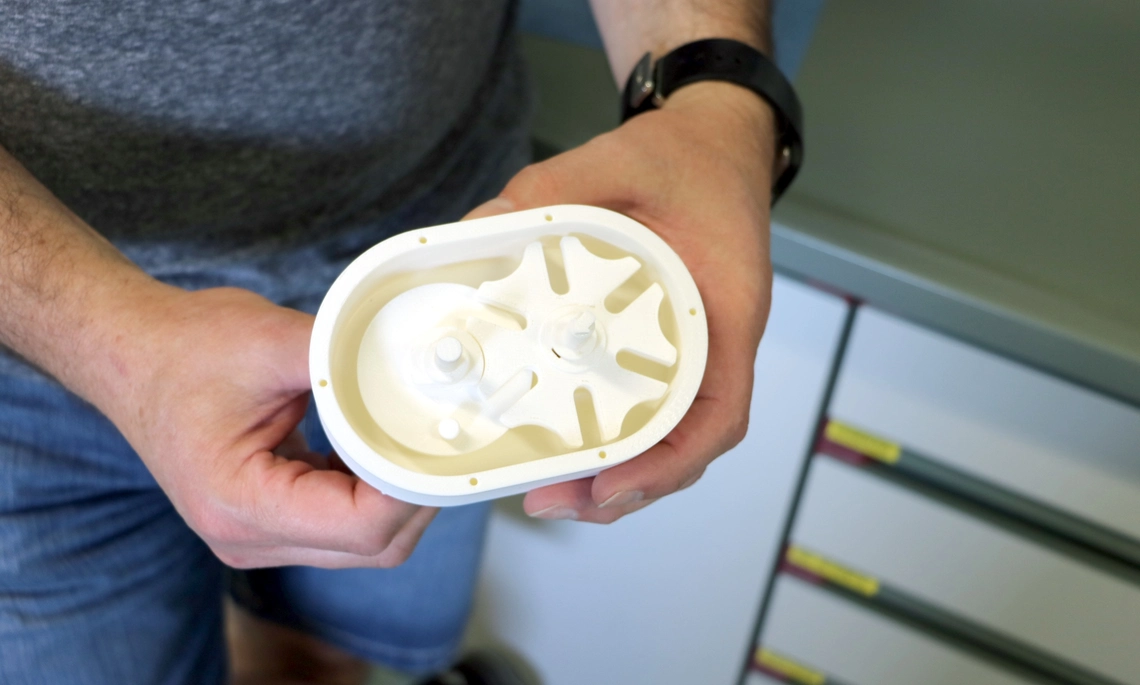

In the "Product Development" laboratory, the procedures of methodical product development are applied and implemented. This means that there is the freedom to realize and test ideas for sophisticated new products in order to create the basis for subsequent industrialization, marketing or spin-offs. To support this, several 3D printers are available or planned in the area of product development, which enable a rapid transformation of ideas into "tangible" products. For "real" products, which also withstand increased mechanical stress, we work together with THI's workshops or with external suppliers. The establishment of this work area in a joint laboratory with "production now" is primarily due to the idea that many of the products to be developed either serve to illustrate a production process or that a production process is necessary for their illustration. In both cases, close interaction with automation technology, software development and data management is required.

Laboratory equipment and activities

- 3D Printers

The laboratory is still under construction and further equipment will be delivered and installed over the coming months.

Construction 3 or product development: A team of students jointly develops a technical solution for a given task.

Industry 4.0, Cyber Physical Prodiction Systems, Information Modelling, Industrial Networking, Lean Development

Laboratory management and team

Prof. Dr.-Ing. Daniel Großmann

Phone: +49 841 9348-2880

Room: D026

E-Mail: Daniel.Grossmann@thi.de

Prof. Dr.-Ing. Klaus-Uwe Moll

Phone: +49 841 9348-2750

Room: A122

E-Mail: Klaus-Uwe.Moll@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)