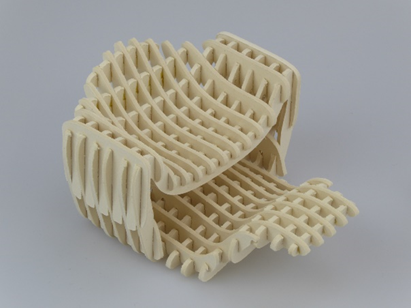

Five Ultimaker 2+ FDM 3D printers are currently available for creating prototypes as part of project work. These are located in laboratory room G190, which also serves as a workroom for the students to post-process the models.

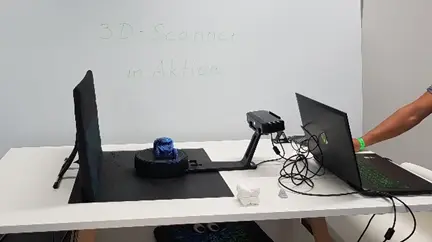

Furthermore, two 3D scanners (EinScan SE - Shining 3D) are available, which make it possible to convert objects back into a CAD model. A 360° scan captures the surface of the object step by step and generates a digital point cloud, which can then be further processed with various CAD programs.

Prototypes with simple, two-dimensional shapes or models based on parametric design can be produced with the help of the Brother DX1500 cutting plotter. This makes it possible to cut out contours from model-making cardboard with a thickness of up to 3 mm, which can then be stuck together. The cutting plotter can also be used to cut adhesive vinyl foils, for example to foil 3D-printed models.

Furthermore, there is a large photo studio in the lab including a digital camera for taking high-resolution product photographs. The white matted shooting table allows models with a size of up to 800 mm and a weight of max. 15 kg to be staged.

In future, students will be able to immerse themselves in the digital world with the help of virtual reality glasses. The PC-supported Valve Index and the wireless Pico Neo 3 Pro are available here. This will not only enable students to present models on a 1:1 scale, but they will also be able to design life-size models using the controllers, for example with the app Gravity Sketch.

The Technical Design Laboratory thus already offers THI students a great deal of design freedom for the implementation of creative and innovative projects. The open and hybrid spatial concept of the lab is also intended to stimulate exchange among each other. Good teamwork and open cooperation are the top priorities here!

![[Translate to English:] Panoramaview Designlabor](/fileadmin/_processed_/9/9/csm_Panoramaview_Designlabor_da345602de.webp)

![[Translate to English:] Studentische Aktivitäten im Designlabor](/fileadmin/_processed_/f/5/csm_Zeichnenundskizzieren_f202a244ed.webp)

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)