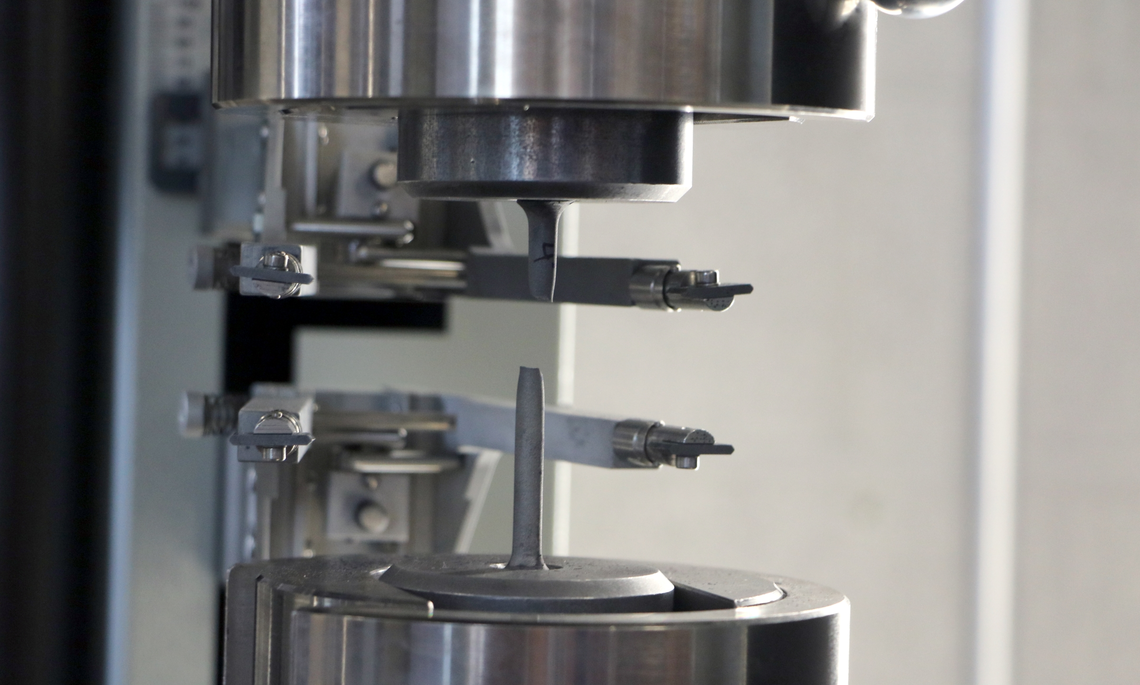

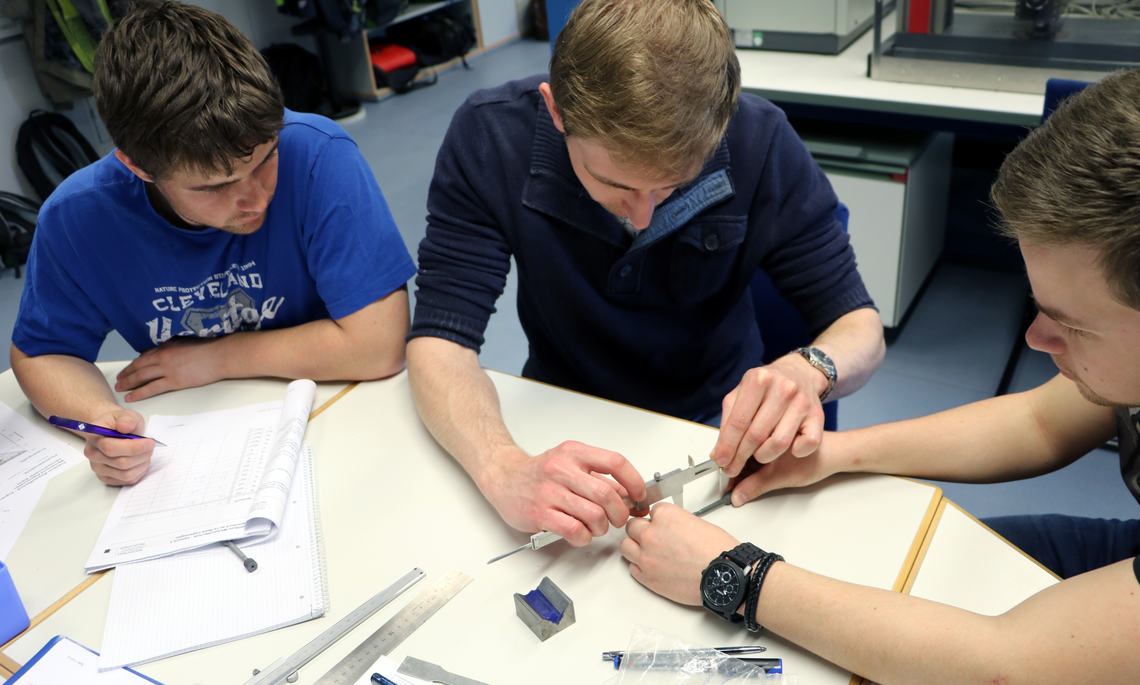

Materials are needed to produce technically relevant components. The mechanical, physical and chemical properties as well as the internal structure determine their usage properties and application possibilities. The characterization of the materials is carried out with the help of analytical methods such as the light microscope, the scanning electron microscope with EDX unit, an XRF and a spark spectrometer. Mechanical parameters are determined by means of tensile testing, notched bar impact testing, hardness measurements and tribology.

Goals and idea

The laboratory serves to train students in the fundamentals of materials engineering for all courses of study. In addition to carrying out bachelor and master theses, the laboratory is of course strongly integrated into the lectures and practical courses of the master's degree "Materials Technology in Mechanical Engineering". One focus is on damage analysis of metallic components. In addition, various research and industrial projects are scientifically accompanied and carried out.

Laboratory equipment and activities

Equipment and function

- Scanning electron microscopy LEO 1430, EDX and EBSD unit of Bruker company (element and structure analysis)

- Microscopy: Incident light microscopes from Leica and Olympus (3D), magnifications 50x - 1000x

- Sample preparation for light microscopy: Equipment from Struers (separating machine, hot embedding press, grinding and polishing machine)

- Various heat treatment furnaces

- Alloy analyses: SPECTRO MAX spark spectrometer, X-ray fluorescence analyzer (XRF) Analyticon XL2 air

- Hardness tests: Universal testing device for macro hardness (Brinell, Rockwell, Vickers) Instron Wolpert Testor 930/250, testing device for micro hardness (Vickers) Leica VMHT30M

- Universal testing machines for tensile, compression and flexure tests from Zwick and Instron with up to 10kN or up to 250kN test force

- Non-contact deformation and strain measurement, GOM ARAMIS 3D 5M

- Impact test up to 300 J

- Tribometer WAZAU TRM 1000

Courses

Bachelor:

- Materials Engineering (all courses)

- Internship Materials Engineering

- Materials engineering and strength theory (mechatronics)

Master:

- Composite Materials

- Corrosion and surface technology

- Long-term behaviour of the materials

- Metallurgy of the production process

- High Performance Materials

- Material and failure analysis

- Module Scientific Work

Bachelor and Master theses, projects

Laboratory management and team

Internship representative

Prof. Dr. mont. Annegret Kerschenlohr

Phone: +49 841 9348-1750

Room: A121

E-Mail: Annegret.Kerschenlohr@thi.de

Prof. Dr. mont. Annegret Kerschenlohr

Phone: +49 841 9348-1750

Room: A121

E-Mail: Annegret.Kerschenlohr@thi.de

Materials and production engineering

Prof. Dr.-Ing. Simon Oberhauser

Phone: +49 841 9348-4411

Room: A127

E-Mail: Simon.Oberhauser@thi.de

Prof. Dr.-Ing. Simon Oberhauser

Phone: +49 841 9348-4411

Room: A127

E-Mail: Simon.Oberhauser@thi.de

Programme director and Academic advisor Material Science in Engineering (Master)

Prof. Dr.-Ing. Ulrich Tetzlaff

Phone: +49 841 9348-3520

Room: A232

E-Mail: Ulrich.Tetzlaff@thi.de

Prof. Dr.-Ing. Ulrich Tetzlaff

Phone: +49 841 9348-3520

Room: A232

E-Mail: Ulrich.Tetzlaff@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)