Focus:

- Simulation-based modeling of modular production

- Developing centralized and decentralized scheduling algorithms

- Investigating the algorithms‘ dependencies on dynamics like machine breakdowns

- Goal: Concluding recommendations for the algorithms‘ applications in modular production

Summary:

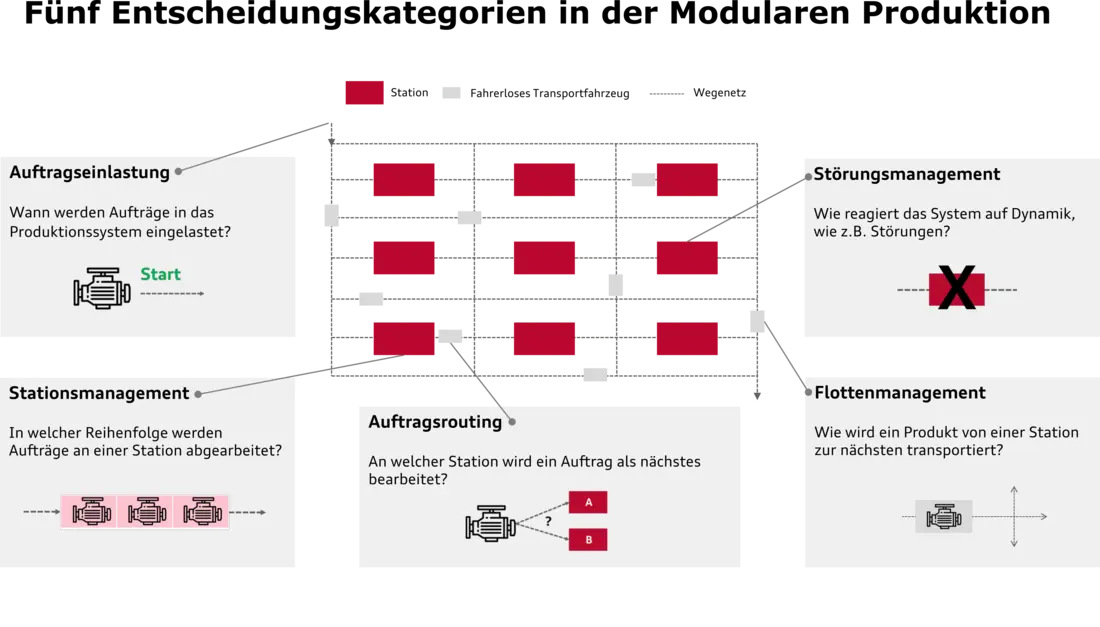

Today, engines are usually assembled in line production. Alternatively, a more flexible modular production concept can be pursued to handle the wide range of variants of future drives such as electric motors. In modular production, automated guided vehicles carry out the material transports between decoupled modular stations. Such modular production offers more flexibility, for instance, a production order can choose different routes through the system to avoid disturbed machines. To benefit from this flexibility, the production control system must provide appropriate decision strategies. The main decision categories are shown in the figure. The PhD project deals with scheduling algorithms making these decisions in a modular production system and investigates their properties depending on the dynamics (e.g. machine disturbances) and the complexity (e.g. number of product types) of the production system. The goal is to achieve an optimal production flow in terms of station and transport vehicle utilization, production order lead times, and production system throughput.

Contact

Prof. Dr.-Ing. Christian Endisch

Phone: +49 841 9348-3368

Room: S 426 (Stauffenbergstr. 2a in the DK building)

E-Mail: els@thi.de

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)