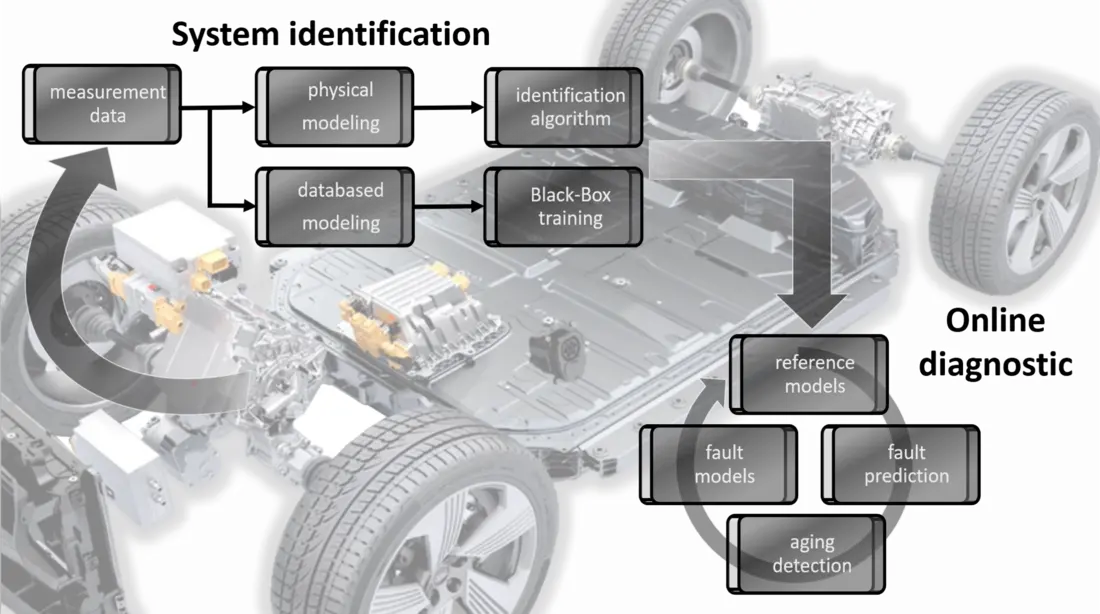

The electric drive train as an alternative to the classic combustion engine will play a central role in future automobiles. One challenge is the development of an efficient control concept for the best possible utilization of the components. Knowledge of the transient behavior of the system parameters is essential for this. The parameters can be determined both online and during operation, as well as offline on the test bench. An advantage of online parameter identification is the additional consideration of unexpected effects. The more accurately the parameters can be determined during operation, the more precisely the current behavior of the system can be described.

In addition to operation-related changes in system parameters, deviations also occur due to production tolerances. Furthermore, the parameters are influenced by aging effects and disturbances due to defects. A robust online parameter estimation allows the detection of malfunctions, since unintended system behavior often results in a violation of physical parameter limits.

In this project a robust online parameter estimation is developed. For this purpose, both model-based and data-based methods of machine learning will be investigated. The overall goal is to derive a diagnostic concept for detecting malfunctions and predicting impending system failure due to aging or defective system components.

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)