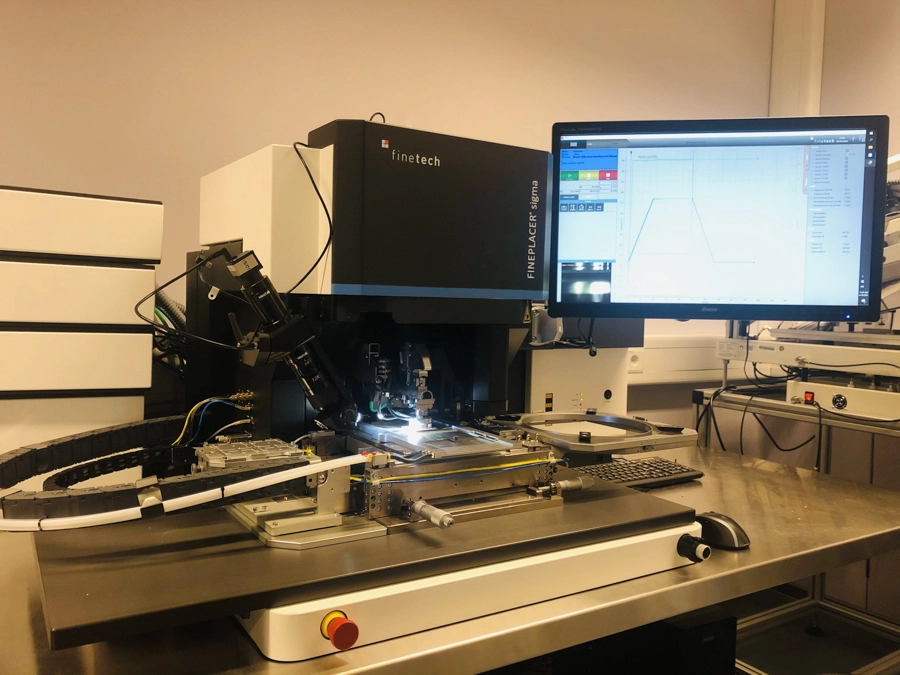

Equipment description

The Fineplacer Sigma as a semi-automatic bonder offers a future-proof assembly and development platform with almost unlimited application possibilities.

- Max. Force = 1000N

- Min. Force = 0.1N

- Component size: 0.5mm2 up to 25mm2

- Sintering under nitrogen, formic acid enriched nitrogen possible

- Tmax = 400°C

- Placement accuracy better than 1µm

- In-situ process monitoring in HD

- UHD Vision Alignment System with FPXvisionTM

- Modular machine platform enables on-site retrofitting over the entire service life

- Wide range of supported component presentations (Wafer, Waffle Pack, Gel-Pak®)

- Integrated Die Picking Module

- Synchronized control of all process-related parameters

- Individually configurable through process modules

- Extensive data/media logging and reporting capability

- Full access to the process and easy visual programming with touch screen

- Numerous supported joining technologies (gluing, soldering, thermo-compression, ultrasound)

- Sequence control with predefined parameters

Equipment information

| Manufacturer | Fineplacer |

| Model | Sigma |

| Location | C307B |

| Contact | Dipl. Ing. (FH) Kirsten Windhorn-Witt |

Laboratory Engineer

Lab engineer

Dipl. Ing. (FH) Kirsten Windhorn

Phone: +49 841 9348-2844

Room: C307

E-Mail: Kirsten.Windhorn@thi.de

Dipl. Ing. (FH) Kirsten Windhorn

Phone: +49 841 9348-2844

Room: C307

E-Mail: Kirsten.Windhorn@thi.de

Open positions

If you are interested in vacancies for student work within the research group, please send an email with CV to assistenz-iimo-elger.de.

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)