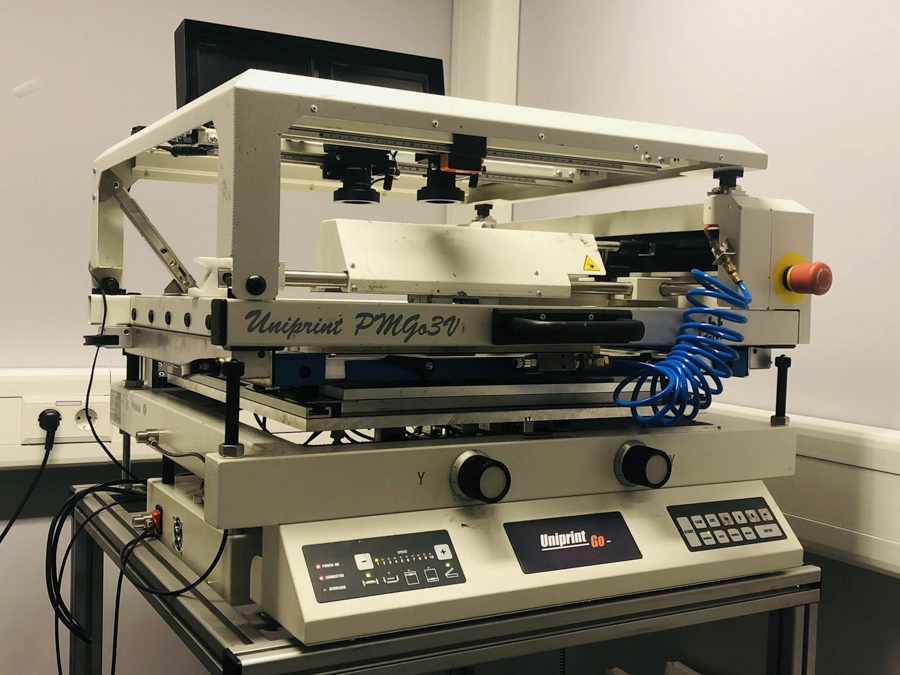

Equipment description

UNIPRINT GO3 is a third generation of table-top exact printing system with camera alignment system and automatic snap-off. This machine has various capabilities such as:

- Motorized squeegee with spring- adjustable print pressure, exactly vertical separation with very fine adjustable snap-off speed.

- Easy and exact re-setting of table vertical position enables a fast change-over for different PCB thicknesses, PCB supporting bars can be easily adjusted upon to PCB thickness.

- Thus an exact level of PCB and squeegee supporting area along the print stroke can be secured. This helps to prolong the stencil lifetime.

- Machine is capable to print small chip structures, BGA, CSP and other similar fine structures.

- A pneumatic servo-system of upper frame balancing helps to open/close upper frame with only minimally force. It is not sensitive to stencil tensioning weight. One can operate with upper frame with only push by finger!

Equipment information

| Manufacturer | PBT-Uniprint |

| Model | PMGo3V |

| Location | C307 |

| Contact | Dipl. Ing. (FH) Kirsten Windhorn-Witt |

Laboratory Engineer

Lab engineer

Dipl. Ing. (FH) Kirsten Windhorn

Phone: +49 841 9348-2844

Room: C307

E-Mail: Kirsten.Windhorn@thi.de

Dipl. Ing. (FH) Kirsten Windhorn

Phone: +49 841 9348-2844

Room: C307

E-Mail: Kirsten.Windhorn@thi.de

Open positions

If you are interested in vacancies for student work within the research group, please send an email with CV to assistenz-iimo-elger.de.

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)