At THI, research and industry go hand in hand. Here, students are trained to become experts in sustainable and safe electromobility. Expertise and equipment for the laboratory for sustainable energy systems come from AVL, among others. In the new research unit, both mobile and stationary lithium-ion battery systems can be tested in continuous operation and under extreme conditions. Ambient temperatures between minus 40 and 90 degrees are possible. New materials can also be tested.

The aim is to maximize the service life, energy efficiency, and reliability of the technology. In the future, the data generated during the test runs will also be processed and analyzed semi-automatically in the cloud. In this way, AVL aims to detect anomalies at an early stage, minimize safety risks, and optimize the performance of batteries.

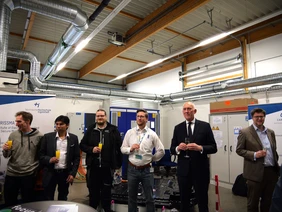

At the opening ceremony, THI President Professor Walter Schober emphasized: ‘We are delighted that we will be able to test the battery technology of the future with the new test bench and that the research results will be passed on directly to our students in teaching.’ Professor Hans-Georg Schweiger, Head of CARISSMA C-ECOS and the Safe Electromobility Research Group, added: ‘The battery test bench from AVL strengthens our long-standing successful collaboration with AVL in research and further education. It offers us a wide range of opportunities to work together on current research issues in the field of electromobility and beyond.’

Dr Andreas Braun, Head of Battery Systems, AVL, added: ‘AVL has a long-standing partnership with the Technical University of Ingolstadt. We are delighted to be able to pass on our experience from industry to the next generation of engineers to prepare them for the challenges of the industry in the best possible way. Because the demands on innovative and sustainable battery technology are growing.’

![[Translate to English:] Logo Akkreditierungsrat: Systemakkreditiert](/fileadmin/_processed_/2/8/csm_AR-Siegel_Systemakkreditierung_bc4ea3377d.webp)

![[Translate to English:] Logo IHK Ausbildungsbetrieb 2023](/fileadmin/_processed_/6/0/csm_IHK_Ausbildungsbetrieb_digital_2023_6850f47537.webp)